An oil refinery is an industrial process plant where crude oil is processed and refined into more useful petroleum products, such as gasoline, diesel fuel, asphalt base, heating oil, kerosine, and liquefied petroleum gas. Refineries are typically large sprawling industrial complexes with extensive piping running throughout, carrying streams of fluids between large chemical processing units. Major products of oil refineries:- Most products of oil processing are usually grouped into three categories: light distillates (LPG, gasoline, naphtha), middle distillates (kerosene, diesel), heavy distillates and residuum (fuel oil, lubricating oils, wax, tar). This classification is based on the way crude oil is distilled and separated into fractions (called distillates and residuum)

• Liquid petroleum gas (LPG)

• Gasoline (also known as petrol)

• Naphtha

• Kerosene and related jet aircraft fuels

• Diesel fuel

• Fuel oils

• Lubricating oils

• Paraffin wax

• Asphalt and Tar

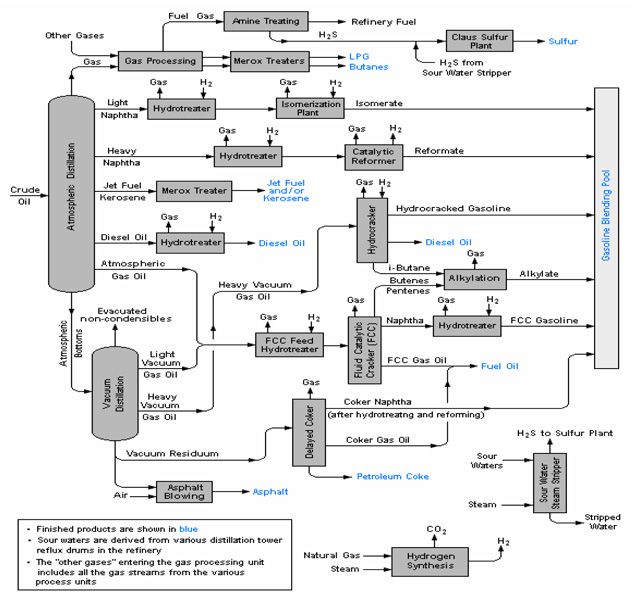

• Petroleum coke Flow diagram of typical refinery

The image below is a schematic flow diagram of a typical oil refinery that depicts the various unit processes and the flow of intermediate product streams that occurs between the inlet crude oil feedstock and the final end products. The diagram depicts only one of the literally hundreds of different oil refinery configurations. The diagram also does not include any of the usual refinery facilities providing utilities such as steam, cooling water,and electric power as well as storage tanks for crude oil feedstock and for intermediate products and end products.There are many process configurations other than that depicted above. For example, the vacuum distillation unit may also produce fractions that can be refined into end products such as: spindle oil used in the textile industry,light machinery oil, motor oil, and steam cylinder oil. As another example, the vacuum residue may be processed in a coker unit to produce petroleum coke.